The latest financial commitment adds 24,000 liters of biologics drug substance-capacity to the company’s network.

The latest financial commitment adds 24,000 liters of biologics drug substance-capacity to the company’s network.

The Identification of Medicinal Product framework seeks to establish a common language for identifying, documenting, and exchanging information about medicinal products.

Acquisition is expected to strengthen company’s CDMO business, while establishing a footprint in the generics space.

Roots Analysis report suggests increase can be attributed to the growing demand for advanced therapies and biologics.

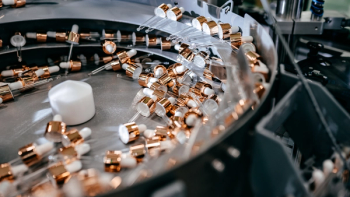

Manufacturers should leverage the knowledge base of personnel working in sterility assurance and in microbiology laboratories.

Review article explores the latest developments surrounding expression and purification strategies.

In the midst of being approved for commercial manufacturing of Pluvict, the 70,000 square-foot site was built specifically to accommodate RLT production.

Provider’s Pithampur facility is recognized for its use of Industry 4.0 technology.

Popular works in the category explore 340B guidelines, ‘smart pharma’ capabilities, and commercialization trends.

The most popular pieces pertaining to the supply chain featured ADMs, vaccine supply chains, and wholesalers.

Study analyzes and predicts how conditions in research and development can be predicted via computer simulation.

While new forms of pharmacy continue to surface beyond brick-and-mortar retail, a look at what is driving this shift in perspective—and "pharmacies of the future"—is warranted.

The CDMO’s GMP plant will dedicate 2,500 square feet to the storage of finished products.

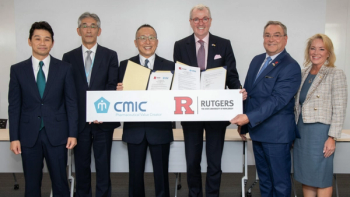

Parties will provide processing and packaging machinery services.

Blue Fin Group exec speaks on his upcoming feature.

SVP and Managing Director for Blue Fin Group offers a synopsis of the conference opener.

Berkeley Research Group executive speaks about the role of manufacturers in 340B pricing.

R&D teams need to accelerate how they conduct their research, get to a material, and get to market.

Determination will affect future vaccine cost and accessibility, including in developing countries.

MarketsandMarkets report points to growth of over $3 billion over the next five years.

How setting action-based goals and cultivating partnerships will help overcome challenges associated with implementing a sustainable GHG strategy.

Parties will establish a Center of Excellence in CMIC’s NJ plant.

Northern Ireland hub undergoes $85 million expansion.

CDMO predicts that its facilities can now potentially produce over $400 million in annual revenue.

CDMO’s goal is to increase building’s aseptic manufacturing capacity.